Main Application

This machine is used to develop and manufacture medium and small-scale integrated circuits, semiconductor devices, acoustic surface wave components.

Because of advanced levelling mechanism and small levelling force, this machine is not only applied to expose silicon wafers, glass wafers, ceramic wafers, gem wafers but also breakable substrates such as K3As and InP, as well as noncircular substrates and small-size substrates.

|

|

Main Structure

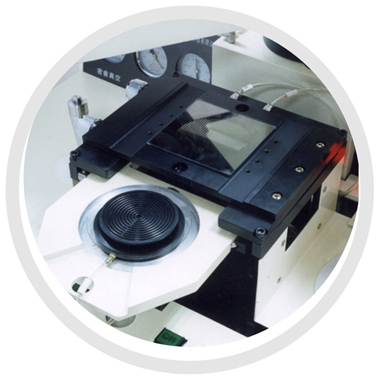

It consists of high degree of accuracy aligning worktable, binocular field-spitting microscope (or CCD micrographic display system), multipoint light source (fly's eye) phtotohead, PLC electric control system, pneumatic system, vacuum pipeline system, monoblock vacuum pump, two levels of vibration-resistance worktable, accessories case, etc..

Main Functional Characteristics

1. Wide Application

It is used to photo-etch all kinds of substrates with diameter below Φ150mm (minimum size is 5×5mm) and thickness below 5mm, including noncircular substrates.

2. High Resolution

Adopting multipoint light source (fly's eye) phtotohead of high uniformity, perfect three-point levelling mechanism and stable and reliable vacuum seal device, exposure resolution of the machine is greatly improved.

3. High Accuracy & High Speed of Aligning

The aligning mode features with underneath type quintuplicate guideway with stationary mask frame and mobile substrate. The load-bearing platform elevating uses spherical guide,pneumatic Z axis mechanism, and twin reed micro- separation mechanism, which enable the contact and separation between the substrate and mask to have small drift, high accuracy and high speed of aligning, thereby the reusability and rate of the finished products are improved.

4. High Reliability

With PLC controller, imported electromagnetic valve, button, unique pneumatic system, vacuum pipeline system and parts which are processed by precision machine production technique, this machine has high reliability and it is very simple and convenient to manipulate, maintain and repair.

5. Special Function of Processing Fragments

It solves the problem that mask frame and substrate can’t be aligned because of adhesion between them, which is caused by noncircular substrates, fragments and uneven bottom surface of substrates.

|

Main specifications

◆ Sizes of Substrates: 6”、5”、4”, thickness:≤5mm

◆ Sizes of Mask Frame:

□7″×7″、□6″×6″、□5″×5″

◆ Aligning Range:

rough adjustment X,Y: ±3mm

fine adjustment: ±0.3mm

rough adjustment Q: ±15°

fine adjustment: ±3°

◆ Aligning Accuracy: ≤1μm

◆ Range of Scan Observation: ≥±15mm

Micro-separation: 0-50μm adjustable

◆ Exposure Range: ≥Φ165mm

◆ Exposure Resolution: 1.5μm

◆ Hard-contact exposure, soft-contact exposure and small-force-contact exposure

◆ Multipoint Light Source (fly’s eye) Phtotohead,

Ununiformity of light:≤±3%, 350-watt Mercury Lamp started by direct current, fan-cooling

◆ Exposure Time: 0-999.9 seconds, adjustable

◆ Luminous Intensity: ≥12mw/cm2, adjustable

◆ Binocular Field-splitting Microscope

Magnification times:30×-375×

Double objective lens distance:20-69mm Or CCD Micrographic Display System

Magnification Times:60×-400×

Double Objective Lens

Distance: 45-150mm

◆ Contact-separation Drift: ≤1μ

◆ PLC controller, imported electromagnetic valve, button, indicator light and timer

◆ Power

Compressed Air: 3.5kg

Voltage: AC220V/50Hz

Power: 1000W

◆ Overall Dimensions:

870×680×1700(L×W×H)

◆ Weight: 180kg

|

Multipoint Light Source

(fly's eye)

Diaphragm with Luminous Iintensity Adjustable

Place-Fetch Mechanism of Push-Draw Mode

Three-Point Levelling MechanismHigh Degree of Accuracy Regulating Mechanism (X, Y, Z,θ)

|

|